- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

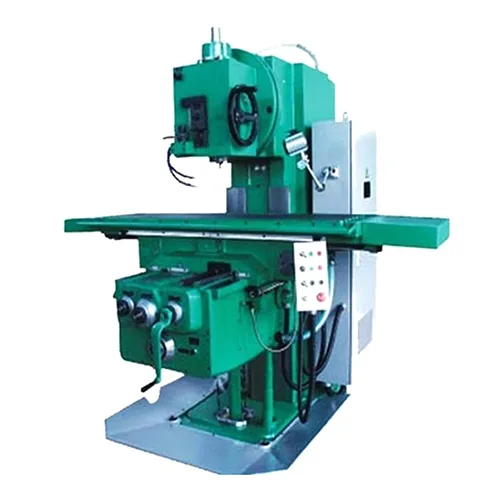

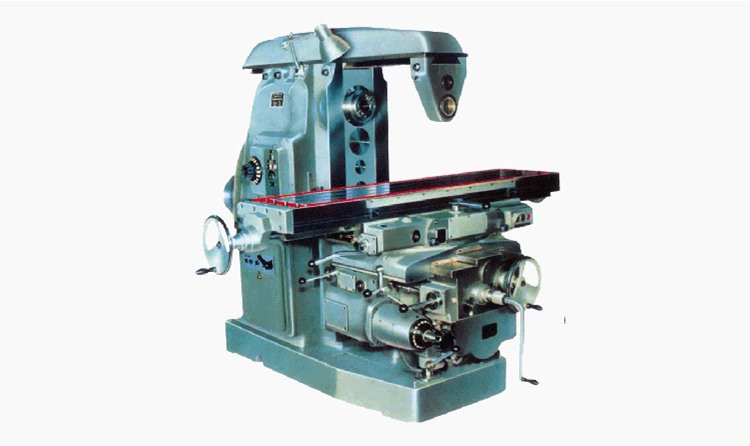

Milling Machine

Milling Machine

Introduction to Milling Machine

Structure and Basic Details

A Milling Machine is a flexible device used in machining tasks to shape strong materials. It routinely includes a proper workpiece and a turning cutting gadget that takes out material from the workpiece to make hand created parts or parts. Handling machines are significant in various ventures, for instance, vehicle, flight, collecting, and improvement.

Product Standards

Processing machines are intended to stick to thorough industry principles, guaranteeing accuracy, sturdiness, and security in their activity. These principles assume a significant part in the assembling and upkeep of processing machines. For example, adherence to ISO 9001 confirmation ensures great administration frameworks, while consistence with ANSI and ASME guidelines directs wellbeing conventions and gear details. By sticking to these principles, producers and administrators can guarantee that processing machines meet the greatest and security prerequisites, giving dependability and true serenity to clients in different ventures.

Basic Parameters

| Parameter | Description |

|---|---|

| Working Area | Length x Width x Height (mm/inches) |

| Spindle Speed | RPM |

| Feed Rate | mm/min or inches/min |

| Power | kW or HP |

| Control System | Manual, CNC |

Product Attributes

Precision: Offers high accuracy in machining operations.

Versatility: Capable of handling various materials and complex shapes.

Efficiency: Provides rapid material removal and reduced machining time.

Durability: Constructed with robust materials for prolonged use.

Flexibility: Accommodates customization for diverse machining tasks.

Product Functions

Cutting: Removes material to create precise shapes and dimensions.

Drilling: Produces holes with accurate depth and diameter.

Profiling: Shapes workpieces according to specific designs.

Slotting: Cuts narrow slots or channels on the workpiece surface.

Features

Spindle Variability: Adjustable spindle speeds for different materials and cutting requirements.

Tooling Options: Compatibility with a wide range of cutting tools for diverse machining tasks.

Control Systems: Manual or CNC control options for operator preference and complexity of operations.

Workpiece Bracing: Secure clipping components to hold workpieces immovably during machining.

Wellbeing Measures: Integrates wellbeing highlights like crisis stop buttons and defensive safeguards

Advantages and Highlights

Enhanced Precision: Achieves intricate designs and tight tolerances.

Increased Productivity: Reduces machining time and enhances workflow efficiency.

Cost-effectiveness: Offers economical solutions for machining operations.

Customization: Tailored solutions to meet specific manufacturing requirements.

Reliable Performance: Consistent and reliable results for various applications.

Application Areas

Automotive: Manufacturing engine components, transmission parts, and chassis.

Aerospace: Fabricating aircraft structures, engine components, and interior fittings.

Manufacturing: Producing prototypes, molds, and tooling for mass production.

Construction: Machining underlying parts, fittings, and installations for structures.

OEM Service

We offer OEM administrations to meet tweaked necessities and particulars. Our group of experienced architects and experts guarantees consistent reconciliation of our processing machines into your assembling processes.

FAQ

Q: What materials can be machined utilizing processing machines?

A: Processing machines can deal with a large number of materials including metals, plastics, wood, and composites.

Q: Could processing machines perform complex machining assignments?

A: Indeed, processing machines are fit for creating perplexing shapes, forms, and surface gets done with high accuracy.

For requests or to put orders, kindly reach us at angie@idlerchina.com.

As an undertaking incorporating logical examination, creation, handling, and deals, we are focused on giving top notch processing machines and excellent client support to address the issues of expert purchasers and worldwide sellers.

The milling machine has two types, horizontal milling machine and vertical milling

machine.It's reliable in structure, good in performance, stable in quality and easy to

operate. It is suitable for various types of machining, such as various planes, grooves, gears, etc. Equipped with other milling machine accessories such as universal milling head, circular table, indexing head, etc., it can further expand the range of application.

Hot Tags: milling machine, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Conveyor Roller Welding Machine, Conveyor Roller Making Machine, CONVEYOR ROLLER PIPE TURNING BORING HOLE MACHINE, Conveyor Roller Assembly Machine Manufacturing, Conveyor Roller Milling Shaft Machine

YOU MAY LIKE