- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Product Overview: Conveyor pulleys are integral components within conveyor systems, serving as the driving force behind the movement of conveyor belts. They play a crucial role in transmitting power and facilitating the efficient transportation of materials. Highlighting their significance underscores their essential contribution to the functionality and performance of conveyor systems.

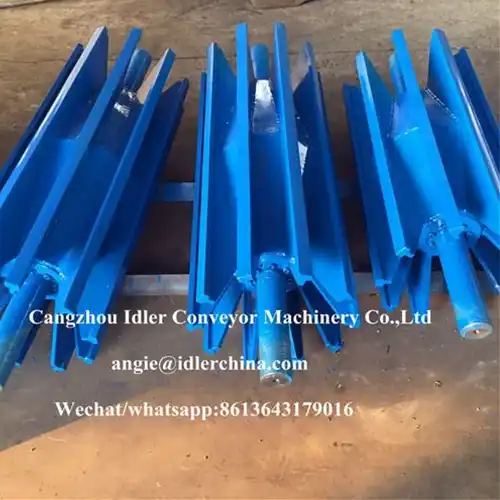

Product Types: Conveyor pulleys are available in various types, including drive pulleys, snub pulleys, and bend pulleys, each designed for specific functions within conveyor setups. These pulleys exhibit unique characteristics tailored to diverse operational requirements, enhancing versatility and adaptability. Visual aids such as images or diagrams can enhance comprehension of the different pulley types.

Material and Manufacturing Processes: Conveyor pulleys are typically crafted from materials such as steel, rubber, or composites, with manufacturing processes encompassing machining, casting, or vulcanization. The choice of material and manufacturing technique significantly influences pulley performance and durability, necessitating careful consideration during selection.

Technical Specifications: Providing technical specifications such as diameter, face width, and shaft diameter assists users in selecting pulleys suitable for their specific applications. Common specifications and models, accompanied by technical parameter tables, facilitate informed decision-making and compatibility assessment.

Application Areas: Conveyor pulleys find widespread application across industries such as mining, manufacturing, logistics, and construction. Their pivotal role in driving conveyor belt movement underscores their importance in facilitating material handling operations and ensuring operational efficiency within diverse industrial settings.

Quality Control and Certification: Emphasizing quality control measures, adherence to standards such as ISO 9001 and CE certification serves as indicators of product quality and compliance. Insights into the supplier's quality management system and product quality assurance measures instill confidence in the reliability and performance of conveyor pulleys.

Conveyor Belt Pulley Types

Conveyor Belt Pulley Types The conveyor belt pulley is an im...

View More

Belt Conveyor Steel Head Drive Drum Pulley

Belt conveyor steel head drum pulley is the main component o...

View More

Deflector Pulley For Belt Conveyor

Deflector Pulley for Belt Conveyor Features:<br>1.High stren...

View More

Belt Conveyor Hot Vulcanized Rubber Coated Drum Pulley

Belt Conveyor Hot Vulcanized Rubber Coated Drum Pulley Types...

View More