- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Conveyor Roller Sets

Conveyor Roller Sets

Introduction to Conveyor Roller Sets

Structure:

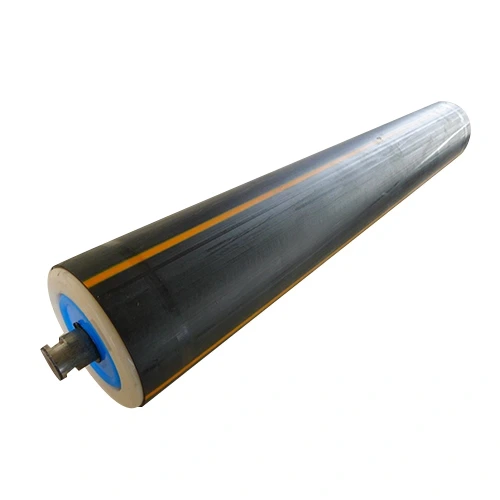

Basic Details of the Product:Conveyor roller sets are integral components in conveyor systems, facilitating the smooth and efficient movement of goods and materials across various industries. These sets consist of multiple rollers assembled in a frame, designed to support and guide conveyor belts or other conveying surfaces.

Product Standards:Our products adhere to rigorous industry standards, ensuring reliability, durability, and safety in operation. They meet or exceed international quality certifications, assuring customers of their performance and longevity.

Product Attributes:

Robust construction for heavy-duty applications.

Low maintenance requirements.

Smooth and quiet operation.

Compatibility with various conveyor systems.

Resistance to corrosion, abrasion, and impact.

Product Functions:

Conveyor roller sets play a crucial role in material handling processes, facilitating the movement of items along conveyor lines with precision and efficiency. They support the weight of conveyed goods, minimizing friction and ensuring smooth transportation.

Features:

Roller Types: Products are available in various types to suit different applications. Common types include troughing rollers, impact rollers, return rollers, and training rollers. Each type serves a specific function, such as supporting the belt, absorbing impact, maintaining belt alignment, or reducing spillage.

Materials: Transport rollers are regularly built from materials like steel, elastic, or polymer composites. The choice of material depends upon factors like weight limit, biological conditions, and the kind of materials being conveyed. Steel rollers are strong and reasonable for uncompromising applications, while elastic rollers offer sound decrease and effect ingestion properties.

Bearing Type: The bearing type used in conveyor rollers determines their efficiency and lifespan. Common bearing types include precision ball bearings, tapered roller bearings, and sealed bearings. High-quality bearings reduce friction, minimize maintenance requirements, and ensure smooth rotation of the rollers.

Sealing Mechanisms: Products may feature sealing mechanisms to protect the bearings from dust, moisture, and contaminants. Sealed rollers help extend the lifespan of the bearings and reduce the risk of breakdowns due to foreign particles entering the bearing housing.

Adjustability: Some conveyor roller sets offer adjustable features to facilitate easy installation and maintenance. Adjustable brackets or frames allow for fine-tuning the roller positions to ensure proper belt tracking and alignment, enhancing the overall performance of the conveyor system.

Advantages and Highlights:

Enhanced productivity and workflow efficiency.

Reduced downtime and maintenance costs.

Improved worker safety.

Compatibility with different conveyor configurations.

Customization options to meet specific requirements.

Application Areas:

They find applications across a wide range of industries, including:

Manufacturing

Warehousing and distribution

Mining and aggregates

Food processing

Logistics and transportation

OEM Service:

We offer OEM services to meet the unique requirements of our customers. Our experienced team can collaborate with clients to develop customized conveyor roller sets tailored to their specific needs and applications.

FAQ:

Q: What materials are available for the rollers?

A: Our rollers can be built from different materials, including steel, PVC, and others, contingent upon the application's prerequisites.

Q: Can you provide customization options?

A: Yes, we offer customization services to ensure our products meet your exact specifications and application needs.

As an enterprise integrating scientific research, production, processing, and sales, we are committed to delivering high-quality products that meet the demands of professional buyers and global dealers. For requests or to submit a request, if it's not too much trouble, reach us at angie@idlerchina.com.

Conclusion:

They are essential components in material handling systems, offering durability, reliability, and efficiency in various industries. With our obligation to quality and customization, we intend to meet the different necessities of our clients around the world.

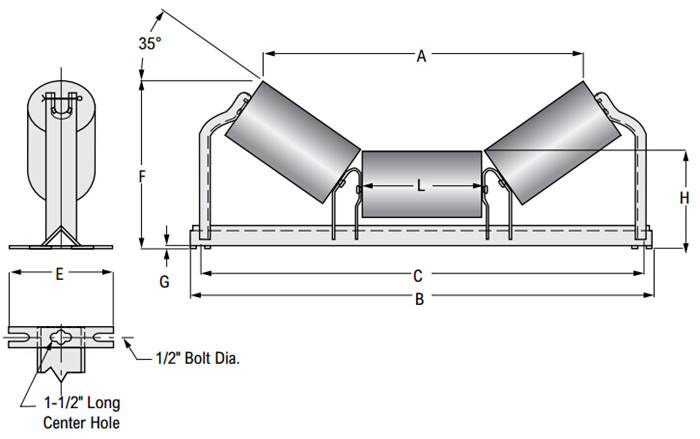

Troughing Carrying Idler are used for conveying bulk materials.They are designed and manufactured with troughing angles of 20°,35°,45° and also can produce as per customers’ requirements. Standard: CEMA,DIN,JIS,DTII

Hot Tags:conveyor roller sets, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Conveyor Belt Idler Rollers, Conveyor Roller Sales, Belt Conveyor Roller, Conveyor Troughing Roller, Belt Conveyor Roller Design, Conveyor Roller Sets

YOU MAY LIKE