- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

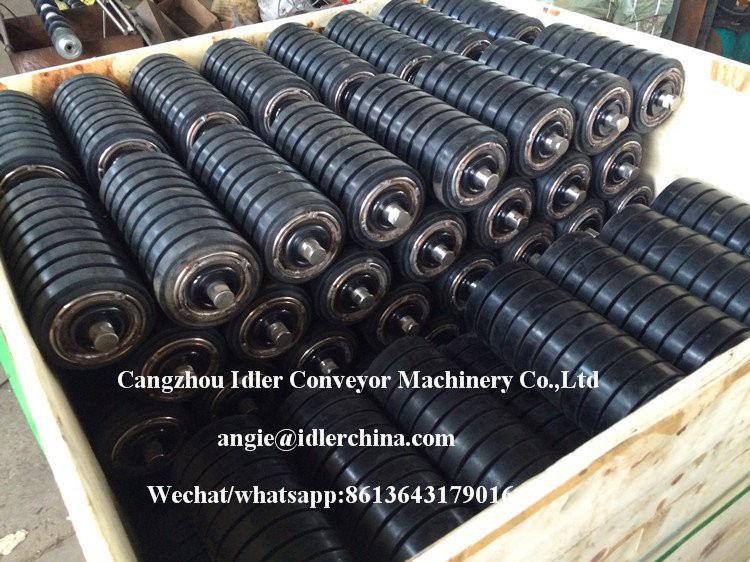

Rubber Ring Coated Impact Roller

Rubber Ring Coated Impact Roller

1. Absorbs weight and shocks;

2. High loading capacity;

3. Highly-effective labyrinth seals protected from dust & water into the bearing;

4. Designed and manufactured for a long, trouble-free life;

5. Maintenance-free, high-quality sealed ball bearing.

Introduction to Rubber Ring Coated Impact Roller

The rubber ring coated impact roller is an essential component in conveyor systems, designed to handle heavy loads and withstand impact forces while ensuring smooth material transportation. These rollers consist of a steel shell with a rubber coating, strategically engineered to absorb shock and protect both the conveyor belt and conveyed materials.

Product Standards:

Our products adhere to stringent industry standards, ensuring durability, reliability, and safety in operation. These standards include but are not limited to ISO 9001:2015, CE, and ANSI/CEMA.

Basic Parameters:

The following table outlines the basic parameters of our products:

| Parameter | Value |

|---|---|

| Diameter | 89mm - 219mm |

| Length | Customizable |

| Shaft Diameter | 20mm - 50mm |

| Bearing Housing Type | Ball Bearing or SKF |

| Rubber Hardness | 60-70 Shore A |

| Load Capacity | Up to 6,000 N |

Product Attributes:

High-quality steel shell for robustness and longevity

Abrasion-resistant rubber coating for enhanced durability

Superior shock absorption capabilities

Low noise and vibration during operation

Easy installation and maintenance

Product Functions:

Absorbs impact and reduces material spillage

Protects conveyor belt from damage

Ensures smooth and efficient material handling

Minimizes downtime and maintenance costs

Features:

Innovative design for optimal performance

Precision-engineered for reliability

Suitable for various industries and applications

Customizable options available to meet specific requirements

Advantages and Highlights:

Exceptional durability, extending conveyor system lifespan

Enhanced safety for personnel and equipment

Improved material handling efficiency

Cost-effective solution with low maintenance requirements

Application Areas:

The rubber ring coated impact roller finds wide applications in industries such as mining, cement, steel, ports, and recycling plants, where heavy-duty material handling is required.

OEM Service:

We offer OEM services to meet the unique requirements of our clients, including custom designs, branding, and packaging solutions.

FAQ:

Q: Can the rubber ring coated impact roller withstand extreme temperatures?

A: Yes, our rollers are designed to perform reliably in a wide range of temperatures, from -40°C to 80°C.

Q: Are custom sizes available?

A: Yes, we offer customization options to accommodate specific conveyor system requirements.

As an enterprise integrating scientific research, production, processing, and sales, we are committed to delivering high-quality products that meet the needs of our customers. For inquiries or orders, please get in touch with us at angie@idlerchina.com.

Conclusion:

Our products offer unmatched durability, performance, and reliability for conveyor systems in various industries. With our commitment to quality and customer satisfaction, we are the preferred choice for professional buyers and global dealers seeking premium conveyor components.

Company Introduction:

We Cangzhou Idler Conveyor Machinery Co., Ltd can produce a complete range of conveyor rollers for bulk materials handling applications in mining, quarrying, recycling, cement, brick, power, grain, and other conveyor type handling systems. Our conveyor roller range includes carrier roller, trough roller, return roller, rubber disc rubber ring coated impact roller and sleeve roller, friction roller, guide roller, and designs with idler roller diameters from 50 mm to 219mm in both carbon steel, stainless steel, PVC, Nylon, and UHMWPE (polymer) across conveyor belt width up to 3500mm.

Rubber Ring Coated Impact Roller Introduction:

Rubber impact roller is used in the loading zone and transfer point applications. The rubber discs are assembled onto a heavy duty steel roller, it which can protect the belt where the lumps, weight, or shape can cause damage to the belt cover from the free fall of material. The rubber ring coated impact roller is standardized and designed according to international standards.

Rubber Ring Coated Impact Roller Specification:

Roller Diameter: 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 219mm

Roller Length: 100-2400mm.

Shaft Diameter: 20, 25, 30, 35, 40, 45, 50mm

Bearing type: 6204, 6205, 6305, 6206, 6306, 6307, 6308, 6309, 6310

Standard: DIN, CEMA, JIS, AS, SANS-SABS, GOST etc.

Rubber Ring Coated Impact Roller features:

1. Absorbs weight and shocks;

2. High loading capacity;

3. Highly-effective labyrinth seals protected from dust & water into the bearing;

4. Designed and manufactured for a long, trouble-free life;

5. Maintenance-free, high-quality sealed ball bearing.

The size and hardness can be customized as per client's requirements

Rubber Ring Coated Impact Roller Product Show

Hot Tags: rubber ring coated impact roller, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Plastic Conveyor Roller, Conveyor Impact Roller, Conveyor Sleeve Roller, Heavy Duty Conveyor Rollers, Metal Conveyor Rollers, Plastic Conveyor Rollers

YOU MAY LIKE