- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Conveyor Belt Pulley Types

Conveyor Belt Pulley Types

According to the role of the pulley in the conveyor, the conveyor belt pulley is divided into two types:

Drive conveyor pulley and Bend conveyor pulley. The function of the drive pulley is to...

Basic Details of the Product:

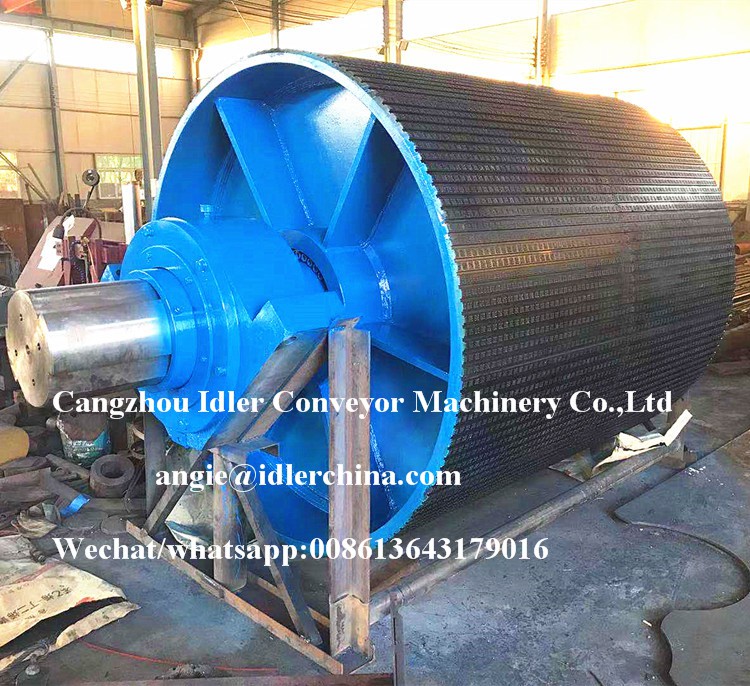

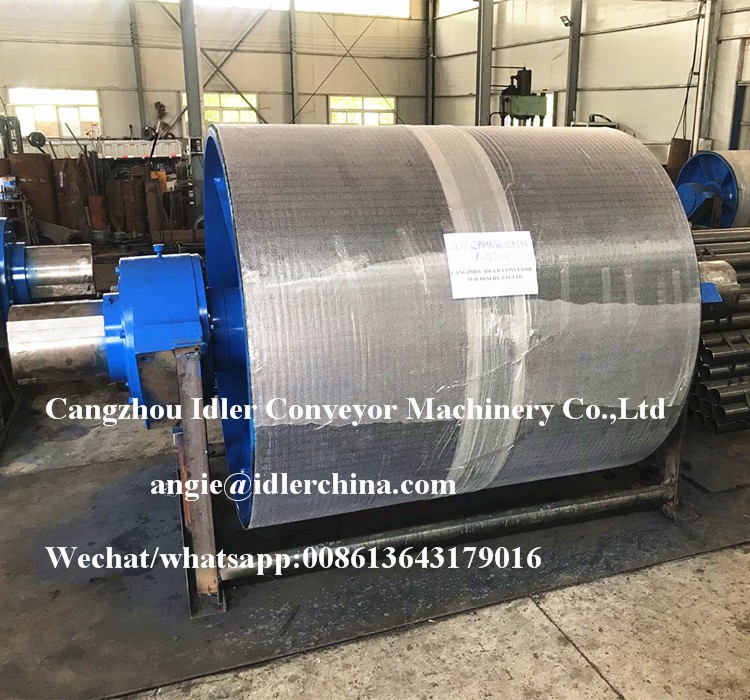

Pivotal to the operation of conveyor systems, Conveyor Belt Pulley Types serve as the propelling mechanism for material transportation along the belt. Distinguished by a variety of types, each tailored to meet precise application needs, these pulleys are typically classified according to their construction, materials, and operational attributes.

Basic Parameters:

Factors such as diameter, facial breadth, hub diameter, shaft dimensions, and the material composition play pivotal roles in defining the efficacy and appropriateness of the product for distinct operational scenarios. These parameters intricately influence the operational dynamics and functional integrity of the pulley systems, thereby underscoring the criticality of precision engineering in this realm. Achieving optimal performance hinges on a meticulous calibration of these specifications to ensure seamless functionality and sustained reliability in industrial settings. As such, a nuanced understanding and meticulous consideration of these intricate details are imperative for enhancing operational efficiency and longevity in conveyor systems.

Product Attributes:

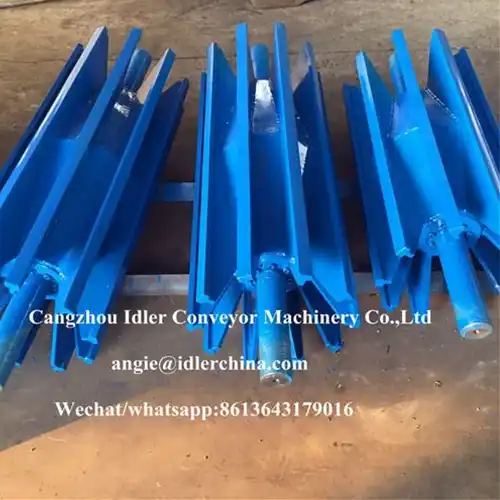

Conveyor Belt Pulley Types are recognized for their robustness, meticulous engineering, and capacity to endure substantial loads and challenging operational environments. They are offered in a range of setups, such as drive pulleys, tail pulleys, bend pulleys, and snub pulleys, tailored to accommodate diverse conveyor designs and specifications.

Product Functions:

The primary function of the product is to transmit power and torque from the drive source to the conveyor belt, facilitating material movement along the conveyor line. They ensure smooth operation, minimal belt slippage, and efficient power transmission.

Features, Advantages, and Highlights:

High-quality construction materials such as steel, stainless steel, and composite materials ensure longevity and resistance to corrosion.

Precision machining and balanced design minimize vibration and noise, enhancing operational efficiency and safety.

Various surface finishes and lagging options provide enhanced grip and traction, reducing belt slippage and improving overall conveyor performance.

Application Areas:

Conveyor Belt Pulley Types are utilized across an extensive array of sectors, encompassing mining, manufacturing, logistics, agriculture, and construction. Their application spans conveyor systems for bulk material handling, baggage handling, food processing, and various other material transport operations.

OEM Service:

We offer OEM services, providing customized the pulleys tailored to specific requirements and applications. Our experienced engineering team ensures seamless integration and optimal performance in diverse conveyor setups.

FAQ:

Q: What materials are frequently employed in the manufacturing of pulleys? A: Steel, stainless steel, and composite materials are commonly selected for the product, contingent upon specific application demands.

Q: Which materials are typically utilized for the pulleys? A: The products are commonly crafted from steel, stainless steel, and composite materials, selected in accordance with specific application demands.

Basic Product Parameter Standards:

Belt Width | Standard Diameter of Pulley |

500 mm | 500mm |

650 mm | 500mm,630 mm |

800 mm | 500mm,630mm,800mm,1000mm,1250mm,1400 mm |

1000 mm | 630mm,800mm,1000mm,1250mm,1400 mm |

1200 mm | 630mm,800mm,1000mm,1250mm,1400 mm |

1400 mm | 630mm,800mm,1000mm,1250mm,1400 mm |

1600 mm | 630mm,800mm,1000mm,1250mm,1400 mm |

1800 mm | 630mm,800mm,1000mm,1250mm,1400 mm |

2000 mm | 800mm,1000mm,1250mm,1400 mm |

2200 mm | 1000mm,1250mm,1400 mm |

2400 mm | 1000mm,1250mm,1400 mm |

Contact Us:

Please send your demands at angie@idlerchina.com. As an enterprise integrating scientific research, production, processing, and sales, we are committed to providing high-quality products and excellent service to our customers worldwide.

Conclusion:

The products are pivotal components within conveyor systems, delivering durability, accuracy, and productivity for material handling operations. Boasting a diverse array of types, configurations, and customizable features, they present adaptable answers to a spectrum of industrial requirements.

Hot Tags: conveyor belt pulley types, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Carbon Steel Belt Conveyor Pulley Manufacturer, Conveyor Tail Pulley, Conveyor Pulley, Rubber Lagging Conveyor Pulley, Ceramic Lagging Belt Conveyor Pulley, Conveyor Drum Pulley

YOU MAY LIKE