- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

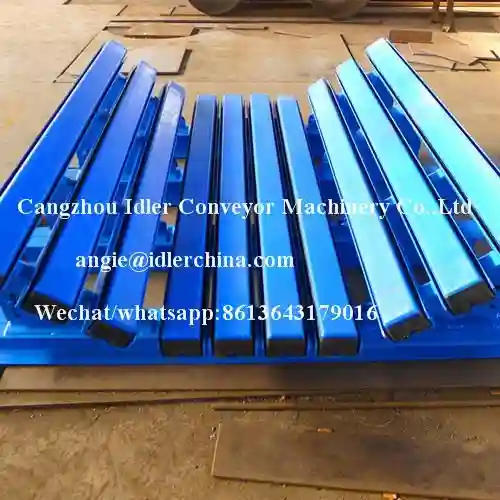

Conveyor Plough Tripper

Conveyor Plough Tripper

1.variable-angle trough (groove angle are 20 °, 30 °, 35 °), to ensure that materials can be run without throwing expected, scattering materials.

Introduction:

As a leading enterprise integrating scientific research, production, processing, and sales, we are proud to introduce our innovative Conveyor Plough Tripper. With a commitment to excellence and precision engineering, our product offers unparalleled performance and reliability in the material handling industry. Designed to meet the rigorous demands of modern industrial applications, our tripper sets the standard for efficiency and versatility.

Product Overview:

The product is a crucial component in conveyor systems, designed to efficiently divert bulk materials off the conveyor belt at designated discharge points. It comprises a sturdy structure equipped with a plough mechanism that can be hydraulically or mechanically operated to direct materials onto alternate conveyors, storage bins, or processing equipment. This versatile solution enhances operational flexibility and streamlines material handling processes across various industries.

Product Standards:

Our Conveyor Plough Tripper adheres to stringent quality standards to ensure optimal performance and safety. Below are the basic parameter standards:

| Parameter | Specification |

|---|---|

| Material Handling | Bulk Materials |

| Power Source | Hydraulic/Mechanical |

| Operating Voltage | 110-480V |

| Belt Width Range | 500mm - 2000mm |

| Tripper Angle Range | 30° - 90° |

| Construction Material | Steel Alloy |

Product Attributes:

Robust construction for durability and longevity

Precision-engineered plough mechanism for efficient material diversion

Adjustable tripper angle for customizable discharge points

Easy installation and maintenance for enhanced operational efficiency

Compatibility with various conveyor systems for seamless integration

Product Functions:

Diverts bulk materials off the conveyor belt at specified locations

Facilitates efficient material distribution and processing

Minimizes material spillage and conveyor belt wear

Optimizes workflow and reduces downtime in material handling operations

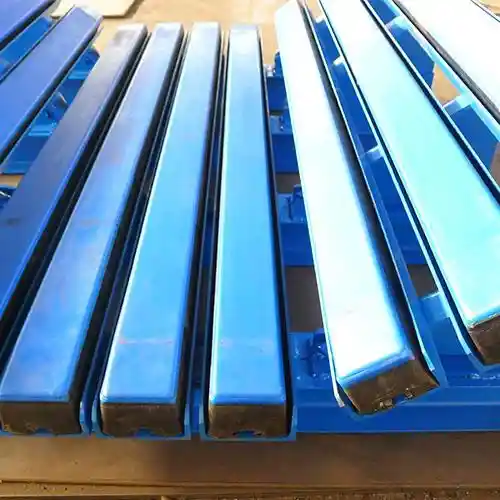

Features:

Variable-angle trough (groove angles are 20 °, 30 °, 35 °), to ensure that materials can be run without throwing expected, scattering materials.

Song coerulea tight regulation of institutions, can always keep close to Plowshares tape face, strong shocks do not shake, beat, is expected to avoid leakage.Spring, vice-plow, so that the plow in pace with tape surface, the second can discharge all of the powdered material into the hopper to clean and meet all the requirements of the industry.a unique form (with arc-shaped, triangular, at the end of the triangle), a decrease of materials on the local impact, discharging more smoothly.

Roller group transform trough-shaped sensitive adhesive tape may work with the flat surface, to ensure that the belt surface and the formation of close to Plowshares.

Frame composition, the installation crew, maintenance, easy maintenance.

Photoelectric switch can be installed close to switching and routing switches, so that this machine has a very good device, hand-cranked device can be controlled coerulea ups and downs, too late to be able to guarantee failure in the maintenance of the normal work, do not delay discharge (Optical switches and switch close to the user needs to configure).

A new type of control box, or the nearest operatives to meet the long-range operations, and program-appropriate.

Advantages and Highlights:

Increases productivity and operational efficiency

Reduces labor costs associated with manual material handling

Enhances workplace safety by minimizing spillage and equipment damage

Improves overall system reliability and uptime

Application Areas:

Mining and Quarrying

Aggregate Processing

Cement Production

Port Terminals

Power Plants

Bulk Material Handling Facilities

OEM Service:

We offer OEM services to meet specific customer requirements, including customized designs, branding, and packaging. Our experienced engineering team ensures seamless integration of our Conveyor Plough Tripper into existing conveyor systems.

FAQ:

Q: What is the lead time for ordering the trippers?

A: Lead times may vary depending on order specifications and quantity. Please contact us for detailed information regarding lead times and availability.

Q: Can the product be installed on existing conveyor systems?

A: Yes, our product is designed for easy integration with various conveyor systems. Our technical support team can provide assistance with installation and retrofitting.

For inquiries or to place an order, please contact us at angie@idlerchina.com. Experience the unmatched performance and reliability of our tripper for your material handling needs.

Hot Tags: conveyor plough tripper, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Conveyor Plough Tripper, Belt Conveyor Cleaner, Conveyor Belt, Impact Bar

YOU MAY LIKE