- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

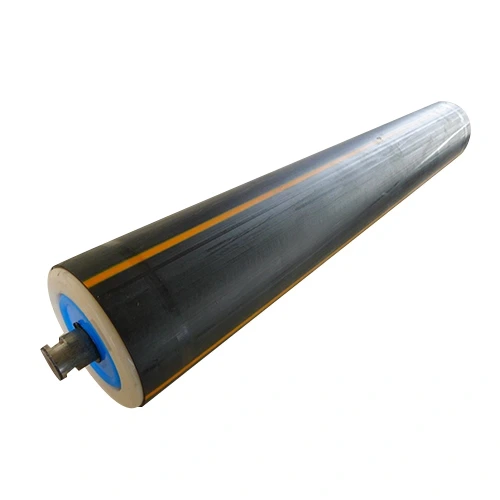

Belt Conveyor Roller Design

Belt Conveyor Roller Design

We Cangzhou Idler Conveyor Machinery Co.,Ltd can produce a complete range of conveyor rollers for bulk materials handling applications in mining, quarrying, recycling, cement, brick,power,grain and other conveyor type handling systems. Our conveyor roller range...

Introduction to Belt Conveyor Roller Design

Product Overview:

Belt conveyor rollers are pivotal components within conveyor systems, facilitating the smooth and efficient movement of goods across various industries. The belt conveyor roller design is precise to withstand rigorous operational demands, ensuring optimal performance and longevity. Crafted from high-quality materials, they are engineered to provide reliable support and guidance for conveyor belts, enhancing productivity and reducing downtime.

Product Standards:

Our belt conveyor rollers adhere to stringent industry standards, ensuring compliance with safety and quality regulations. These standards encompass durability, load-bearing capacity, precision engineering, and resistance to environmental factors, guaranteeing consistent performance in diverse operating conditions.

Product Attributes:

Robust construction for prolonged service life

Smooth and quiet operation

Low maintenance requirements

Excellent load-bearing capability

Resistance to corrosion and abrasion

Product Functions:

Belt conveyor rollers serve crucial functions within conveyor systems:

Supporting and guiding conveyor belts

Facilitating the movement of goods with minimal friction

Distributing loads evenly across the conveyor

Enhancing operational efficiency and throughput

Features:

Precision-engineered for superior performance

The belt conveyor roller design is versatile to suit various conveyor configurations

Easy installation and compatibility with existing systems

Customization options available to meet specific requirements

Advantages and Highlights:

Enhanced reliability and durability

Reduced maintenance costs and downtime

Improved conveyor efficiency and productivity

Consistent performance in demanding environments

Application Areas:

Belt conveyor rollers find extensive use across numerous industries, including:

Mining and aggregates

Manufacturing and logistics

Warehousing and distribution

Food processing and packaging

Agriculture and forestry

OEM Service:

We offer comprehensive OEM services, catering to the unique requirements of clients worldwide. Our experienced team collaborates closely with customers to deliver tailored solutions that meet their specific needs and preferences.

FAQ:

What is the typical lifespan of your belt conveyor rollers?

Our belt conveyor roller design is for longevity, with lifespans varying based on usage conditions and maintenance practices.

Can you customize rollers according to our conveyor specifications?

Yes, we specialize in customization and can tailor rollers to fit your conveyor system perfectly.

Do you provide installation assistance?

While we do not offer installation services directly, our team can provide guidance and support to ensure seamless integration with your conveyor system.

For inquiries or orders, please contact us at angie@idlerchina.com. As an enterprise integrating scientific research, production, processing, and sales, we are committed to delivering premium qualitythe belt conveyor roller design and exceptional service to our global clientele. Trust us for your belt conveyor roller needs, and experience the difference in performance and reliability.

Belt Conveyor Roller Inner Structure

Belt Conveyor Roller Each Part Introduction

1. Manufactured with steel pipe especially for high precision roller, compared with ordinary steel pipe, the diameter and wall thickness tolerance, bending degree, ovality are very little which can make the roller have minimum radial play eccentricity, strong load, low shaking and less noise

2.High precision and brightness cold drawn shaft with 1045 material

3.Rollers are fitted with deep groove 2RS and 2Z bearings with C3 and C4 internal clearance with HRB, SKF, NSK, TNT, FAG brands.

4.Bearing Housing formed by punching many times which can assure high precision. The wall thickness is 1-2mm thicker than the DIN standard which can increase 40% stability and roller's carrying capacity. It can make the roller not deformed even the working under overload an environment and increase the roller's lifetime.

5.TK contact multiple labyrinth seals made of nylon, ABS have great advantage in water and dust resistance.

Hot Tags: belt conveyor roller design, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Steel Conveyor Roller, Conveyor Roller, Conveyor Roller Sales, Heavy Duty Conveyor Rollers, HDPE Conveyor Roller, Conveyor Troughing Roller

YOU MAY LIKE