- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Conveyor Tail Pulley

Conveyor Tail Pulley

Overview:

Conveyor tail pulleys are pivotal components in conveyor systems, facilitating the smooth movement of materials in industries ranging from mining to logistics. These pulleys are strategically positioned at the tail end of conveyor belts, serving to redirect the belt and maintain tension for optimal performance. Comprising a cylindrical shell, shaft, bearings, and locking elements, the pulleys play a critical role in controlling the return side of the belt, ensuring efficient material handling.

Product Standards:

Our products adhere to stringent industry standards, including but not limited to:

ISO 9001: Quality Management Systems

DIN 22107: Continuous Conveyors - Belt Pulleys

CEMA Standards: Conveyor Equipment Manufacturers Association

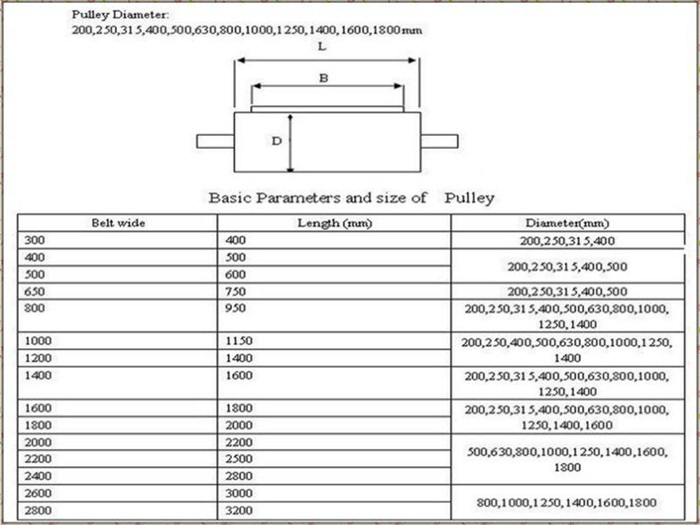

Basic Parameters:

The table below outlines fundamental parameters of our pulleys:

| Parameter | Standard |

|---|---|

| Pulley Body Material | Carbon steel,Alloy steel,Stainless Steel |

| Diameter Range | 200 mm to 2200 mm |

| Shaft Diameter | 40 mm to 600 mm |

| Bearing Type | Spherical roller bearing/Self-aligning ball bearing |

| Surface Treatment | Painted,diamond/herringbone/chevron rubber lagging,replaceable rubber lagging, rubber ceramic lagging, ceramic file lagging |

| Pulley Type | Head drive pulley,bend tail pulley,take-up pulley,motorized pulley,tension pulley |

| Shaft Material | 45# steel, 40CR,42CRMO, SS304,SS321 |

Product Attributes:

Robust construction for durability

Precision-engineered for smooth operation

Corrosion-resistant materials ensure longevity

Easy installation and maintenance

These product attributes embody a commitment to quality and performance, catering to industries seeking reliability, efficiency, and longevity in their operational equipment. The robust construction ensures durability, while precision engineering guarantees smooth and efficient operation. With corrosion-resistant materials, longevity is a staple feature, providing a cost-effective solution for long-term usage. Furthermore, the ease of installation and maintenance enhances user experience, reducing downtime and optimizing productivity across various industrial applications.

Product Functions:

Redirects conveyor belt for efficient material handling

Maintains proper tension on the return side of the belt

Minimizes belt misalignment and tracking issues

Features:

Various diameter and length options for diverse applications

Customizable shaft diameter and surface treatments

Precision bearings for reduced friction and wear

Compatible with different conveyor belt types

Advantages and Highlights:

Enhanced efficiency and productivity in material handling operations

Reduced downtime due to reliable performance and low maintenance requirements

Improved safety with stable belt tracking and reduced wear on conveyor components

Application Areas:

Conveyor tail pulleys find extensive usage across industries such as:

Mining and Quarrying

Manufacturing and Production

Ports and Terminals

Agriculture

Warehousing and Distribution

These precision-engineered pulleys are strategically positioned at the tail end of conveyor belts, playing a pivotal role in redirecting the belt and maintaining optimal tension for seamless material handling. Comprising a meticulously crafted cylindrical shell, precision-engineered shaft, high-performance bearings, and robust locking elements, the products deftly control the return side of the belt, ensuring efficient material conveyance across a spectrum of industrial operations, ranging from mining endeavors to intricate logistical networks.

OEM Service:

We offer OEM services to meet specific customer requirements, including customization of dimensions, materials, and surface treatments. Our experienced team ensures seamless integration with existing conveyor systems for optimized performance.

FAQ:

Q: What materials are available for the conveyor tail pulley? A: We offer tail pulleys constructed from carbon steel, stainless steel, and other materials upon request.

Q: Can you customize the dimensions of the tail pulley to fit our conveyor system? A: Yes, we provide tailored solutions to accommodate varying conveyor belt sizes and specifications.

Please send your demands to angie@idlerchina.com. As a leading enterprise integrating scientific research, production, processing, and sales, we guarantee superior quality and service excellence in every product we deliver. Choose our products for reliable performance and lasting value.

The pulley which is usually installed at the tail part or the vertical take-up equipment part is used for changing the direction of the belt.

Surface treatment:Painted, flat rubber lagging

Hot Tags: conveyor tail pulley, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Ceramic Lagging Belt Conveyor Pulley, Carbon Steel Belt Conveyor Pulley Manufacturer, Rubber Lagging Conveyor Pulley, Wing Pulley, Conveyor Tail Pulley, Conveyor Drive Drum

YOU MAY LIKE