- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

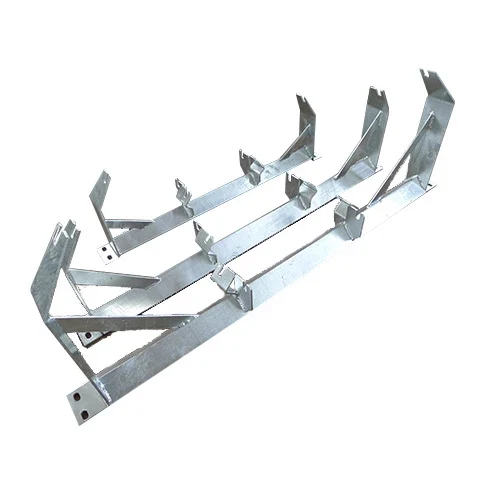

Product Overview: Conveyor idlers are essential components of conveyor systems, playing a pivotal role in supporting and guiding the movement of conveyor belts. They are indispensable for ensuring smooth and efficient operation within conveyor systems. Emphasizing their significance underscores their critical role in maintaining overall conveyor system performance.

Product Types: Conveyor idlers come in various types, including parallel, carrying, and impact idlers, each tailored to specific applications and scenarios. These idlers exhibit distinct characteristics suited for different operational environments, enhancing their versatility and adaptability. Visual aids such as images or diagrams can facilitate better comprehension of the different idler types.

Material and Manufacturing Processes: Conveyor idlers are commonly constructed using materials such as steel, rubber, or polymers, with manufacturing processes including forging, welding, or injection molding. The choice of material and manufacturing method significantly influences the performance and durability of the product, necessitating careful consideration during selection.

Technical Specifications: Providing technical specifications such as load capacity, rotational resistance, and abrasion resistance aids users in selecting idlers best suited for their requirements. Common specifications and models, along with corresponding technical parameter tables, facilitate informed decision-making and product compatibility assessment.

Application Areas: Conveyor idlers find extensive applications across various industries, including mining, ports, logistics, and construction. Their pivotal role in facilitating material handling operations underscores their importance in ensuring operational efficiency and productivity within diverse industrial settings.

Quality Control and Certification: Highlighting the importance of quality control, accreditation standards such as ISO 9001 and CE certification serve as benchmarks for ensuring product quality and compliance. Detailed insights into the supplier's quality management system and product quality assurance measures instill confidence in the reliability and performance of conveyor idlers.

.webp)