- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

1. Introduction to Conveyor Components: Conveyor components encompass a diverse array of elements that work together to form functional conveyor systems. These components include rollers, belts, pulleys, bearings, and accessories, each serving a specific function in the material handling process. From guiding and supporting to driving and controlling, these components play integral roles in the smooth and efficient operation of conveyor systems.

2. Types and Functions of Conveyor Components:

Rollers: Rollers serve as the foundation of conveyor systems, supporting and guiding the movement of goods along the conveyor path. They come in various configurations, including gravity rollers for manual conveying and powered rollers for automated systems.

Belts: Conveyor belts are flexible loops of material that carry goods from one point to another. They are typically made from rubber, PVC, or other materials and are available in different designs to suit specific applications, such as flat belts, modular belts, and timing belts.

Pulleys: Pulleys are cylindrical components mounted at the ends of conveyor belts to facilitate rotation and movement. They come in various sizes and configurations, including drive pulleys, idler pulleys, and snub pulleys, each serving a distinct role in belt tensioning and alignment.

Bearings: Bearings are essential for reducing friction and facilitating smooth rotation within conveyor components such as rollers and pulleys. They come in different types, including ball bearings, roller bearings, and sleeve bearings, chosen based on load capacity, speed, and environmental conditions.

Accessories: Conveyor accessories, such as guides, guards, sensors, and controls, enhance the functionality, safety, and efficiency of conveyor systems. They help prevent material spillage, protect personnel, and enable automated operation through the integration of sensors and control systems.

3. Importance of Conveyor Components: Conveyor components play a critical role in the overall performance and reliability of conveyor systems:

Reliability: High-quality components contribute to the reliability and uptime of conveyor systems, reducing the risk of unplanned downtime and costly maintenance.

Safety: Properly designed and maintained conveyor components ensure safe operation, minimizing the risk of accidents and injuries to personnel.

Flexibility: Modular conveyor components allow for easy customization and adaptation to changing production needs, enabling efficient material handling in diverse applications and industries.

4. Maintenance and Optimization: Regular maintenance and inspection are essential for ensuring the longevity and optimal performance of conveyor components. This includes lubrication, alignment checks, belt tensioning, and replacement of worn or damaged parts. By implementing preventive maintenance measures and leveraging advanced technologies such as predictive maintenance and condition monitoring, industries can minimize downtime and maximize conveyor system efficiency.

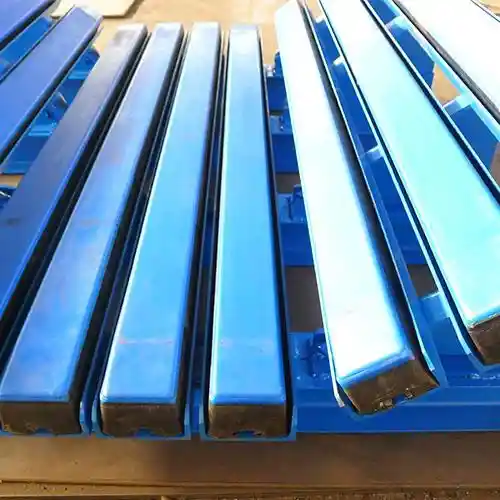

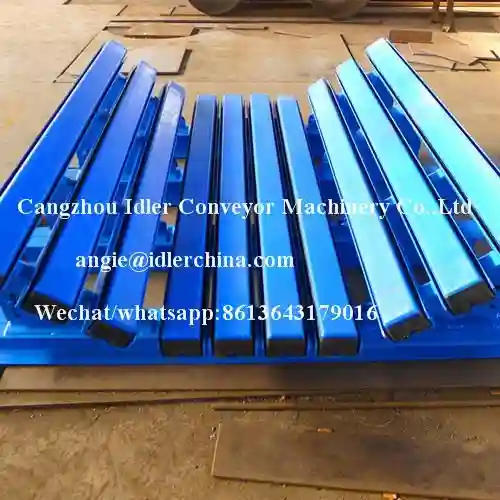

Impact Bed For Belt Conveyor

Impact Bed for Belt Conveyor Advantage: Corrosion Protection...

View More