- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

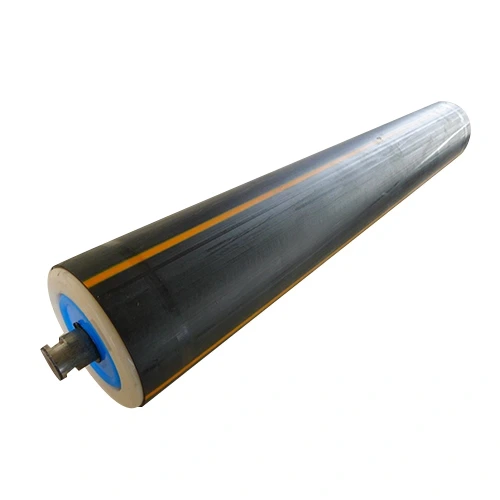

Plastic Conveyor Rollers

Introduction to Plastic Conveyor Rollers

Plastic conveyor rollers are vital components in material handling systems, facilitating the efficient movement of goods in various industries. As a professional buyer or global dealer, understanding the intricacies of these rollers is crucial for optimal system performance and longevity.

roduct Structure:

They are designed in light of accuracy and solidness. These rollers consistently contain first class thermoplastic materials, carefully expected to persevere through the difficulties of diligent movement. They come in different setups, including gravity rollers, driven rollers, and tightened rollers, taking care of assorted application needs.

Product Standards:

Manufacturers adhere to stringent quality standards to ensure the reliability and performance of plastic conveyor rollers. Common standards include ISO 9001 certification, ensuring adherence to quality management systems, and ASTM standards for material properties.

Basic Parameters:

Below are typical parameters for it, presented in table form:

| Parameter | Value |

|---|---|

| Diameter | 20mm - 200mm |

| Length | Customizable |

| Load Capacity | Up to 500 kg per roller |

| Bearing Type | Precision ball bearings |

| Temperature Range | -20°C to 80°C |

| Shaft Options | Mild steel, stainless steel |

Product Attributes:

Lightweight yet durable construction

Low noise and vibration operation

Corrosion-resistant for longevity

Easy installation and maintenance

High load-bearing capacity

Product Functions:

Plastic conveyor rollers facilitate smooth and efficient material transport along conveyor belts. They support loads of varying weights while minimizing friction and wear on the conveyor system. Additionally, these rollers contribute to the overall reliability and productivity of material handling operations.

Features, Advantages, and Highlights:

Lightweight: They are fundamentally lighter than metal rollers, making them more straightforward to deal with during establishment, upkeep, and fixes. Their lightweight nature additionally diminishes the general burden on the transport framework, bringing about better energy proficiency.

Consumption Obstruction: They are profoundly impervious to erosion, dissimilar to metal rollers that might rust or break down when presented to dampness or synthetic compounds.This makes plastic rollers ideal for applications in wet or corrosive environments, such as food processing,chemical industries, and outdoor settings.

Low Clamor and Vibration: They offer phenomenal clamor and vibration hosing properties. The material's in nate qualities assist with decreasing commotion levels in the transport framework, establishing a calmer work space for administrators and lessening the effect of clamor contamination in modern settings.

Self-Lubricating: It for transport rollers have self-greasing up properties. This kills the requirement for extra oil, lessens upkeep necessities, and forestalls issues connected with oil or oil defilement on shipped products.

Application Areas:

Plastic transport rollers track down applications across a large number of businesses, including:

Assembling and creation offices

Warehousing and appropriation focuses

Food and drink handling

Drug and medical care areas

Bundling and strategies enterprises

OEM Service:

As an enterprise integrating scientific research, production, processing, and sales, we offer comprehensive OEM services tailored to meet specific customer requirements. Whether it's custom roller dimensions, specialized materials, or branding needs, our team is equipped to deliver high-quality solutions.

FAQ:

Q: Can plastic conveyor rollers withstand heavy loads?

A: Yes, our plastic rollers are engineered to support loads of up to 500 kg per roller, ensuring reliable performance in demanding applications.

Q: Are plastic rollers suitable for high-temperature environments?

A: Our rollers are designed to operate within a temperature range of -20°C to 80°C, making them suitable for most industrial settings.

For inquiries or to discuss your specific requirements, please contact us at angie@idlerchina.com. Choose our products for unmatched quality and reliability in material handling solutions.

CZXD offers a complete range of it for bulk materials handling applications in mining, quarrying, recycling, cement, brick,power,grain and other conveyor type handling systems.

Material:PVC, Nylon, HDPE/UHMWPE and so on

Hot Tags: plastic conveyor rollers, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Conveyor Idler Roller, Conveyor Belt Rollers, Conveyor Roller Sales, Plastic Conveyor Rollers, HDPE Conveyor Roller, PU Coat Roller

YOU MAY LIKE